9 Simple Techniques For Premier Aluminum Llc

Table of ContentsPremier Aluminum Llc - TruthsThe Ultimate Guide To Premier Aluminum LlcThe Best Guide To Premier Aluminum LlcThe 20-Second Trick For Premier Aluminum Llc

(https://www.reddit.com/user/premieraluminum/)Making use of reduced cost and unqualified distributors can trigger top quality concerns, and lost time and cash in the lengthy run. To aid you via the process, below are some points to consider when selecting the best metal casting supplier.

A firm that just makes use of the investment casting process will try to offer you on why that process is best for your application (Foundry). What if using the sand casting procedure is best for you and your requirements? Instead, try to find a distributor that provides a series of casting processes so the best alternative for YOU is chosen

If collaborating with a solitary source for every one of your spreading needs is crucial to you, the vendor requires to be varied in its capacities. When combined with other incorporated capacities, this can assist simplify and compress the supply base. When picking the ideal spreading supplier, careful consideration should be provided to high quality, service, and cost.

The Main Principles Of Premier Aluminum Llc

Buyers increasingly select spreading vendors who have machining capacities. This can avoid problem if defects are discovered during machining. If a 3rd party is machining, it might lead to "finger-pointing" regarding who is at fault. Is it a casting concern or a machining problem? If the spreading provider finds a concern throughout machining, the trouble is settled faster without disagreement over whose mistake it is.

Trouble or no, incorporated machining simplifies the supply chain and lowers managing time and shipping cost before the item makes it to the client. What do you need from your spreading provider? Are you trying to find a person to simply deliver a metal component to your front door or do you require extra? As an example, if you do not have in-house metallurgy know-how, verify that the vendor can supply advice in selecting the appropriate alloy based on your details application - Aluminum Casting.

Others will go beyond the letter of the PO to help you conserve time and cash. Do you have needs for both ferrous and non-ferrous alloys? Some factories are limited or specialized. Ensure the vendor can satisfy all your product or alloy demands to remove the requirement for multiple distributors.

Getting The Premier Aluminum Llc To Work

Research the supplier's web site. Talk to a sales representative or organization partner.

Aluminum is likewise lightweight and has good corrosion resistance, making it ideal for applications where weight and sturdiness are very important variables. In addition, light weight aluminum casting is a cost-effective technique of production, as it calls for less power and resources than various other methods. Iron casting, on the various other hand, involves putting molten iron right into a mold and mildew to produce a preferred form.

The Definitive Guide for Premier Aluminum Llc

Iron spreading is likewise able to withstand high temperature levels, making it ideal for usage in applications such as engine parts and industrial machinery. However, iron spreading can be more costly than light weight aluminum casting as a result of the higher expense of basic materials and find more information the energy required to melt the iron. When deciding in between light weight aluminum spreading and iron casting, it is necessary to take into consideration the specific requirements of the application.

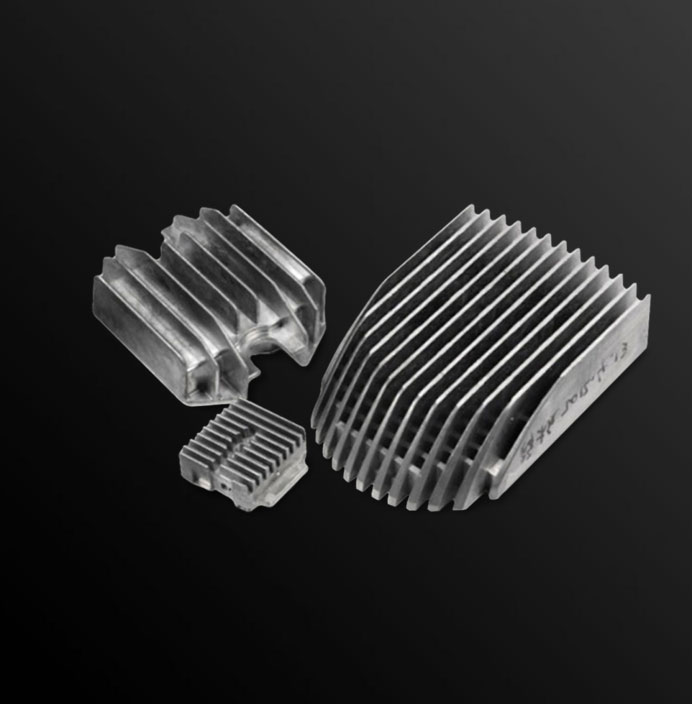

In final thought, both aluminum casting and iron casting have their very own one-of-a-kind benefits and drawbacks. There are three sub-processes that fall under the group of die casting: gravity pass away casting (or irreversible mold spreading), low-pressure die spreading and high-pressure die spreading. To get to the completed item, there are three primary alloys utilized as die spreading product to choose from: zinc, aluminum and magnesium.